Filter the result

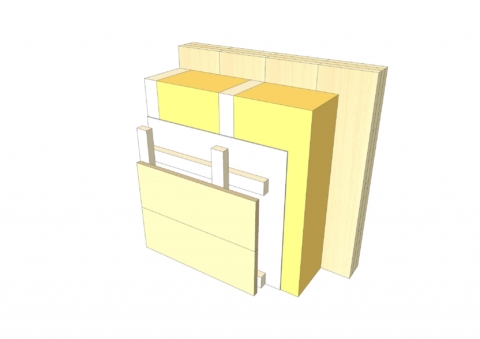

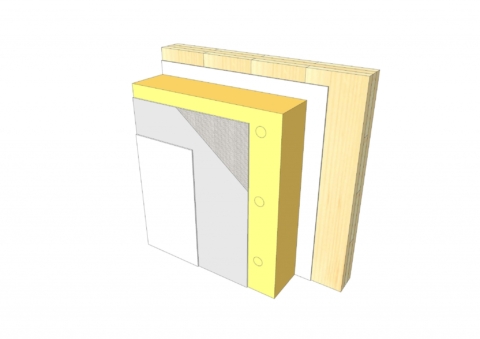

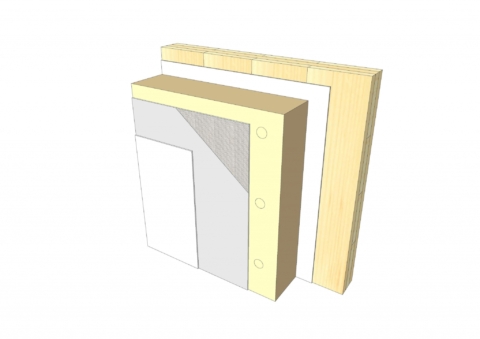

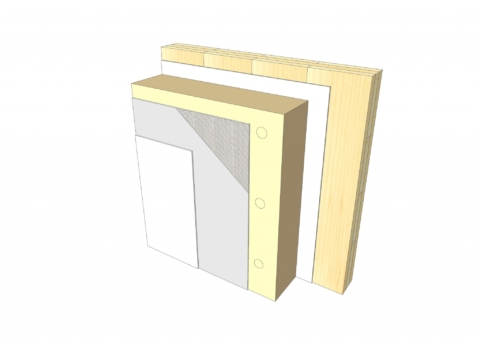

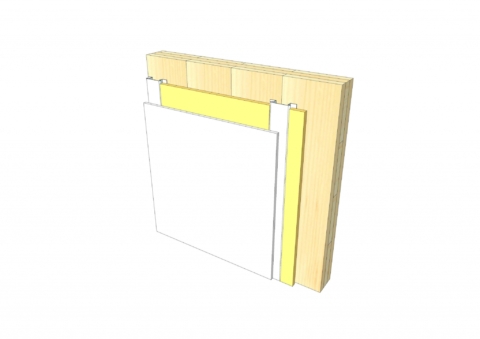

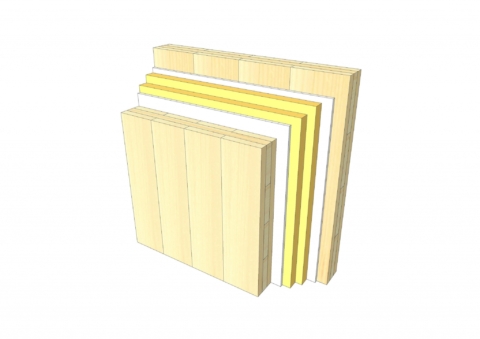

AW_01 | Ventilated timber facade

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

44

0.17

30

391

-89

45

0.17

60

403

-87

52

0.16

60

430

-85

55

0.14

90

463

-81

63

0.14

90

476

-80

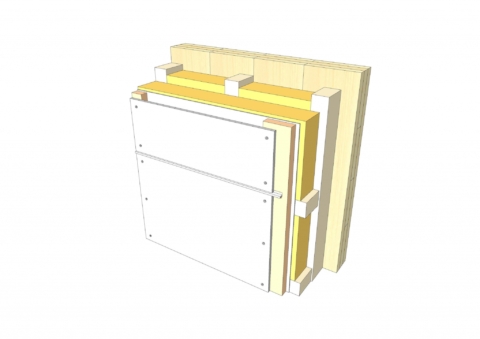

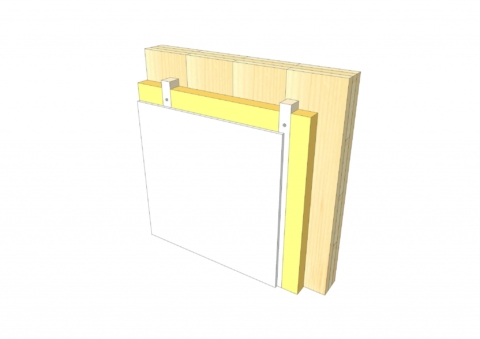

AW_02 | Ventilated facade panel

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

53

0.17

30

343

-46

54

0.17

60

355

-44

58

0.16

60

382

-42

60

0.14

90

418

-37

66

0.14

90

428

-37

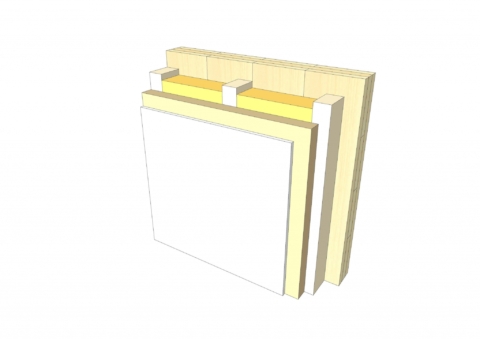

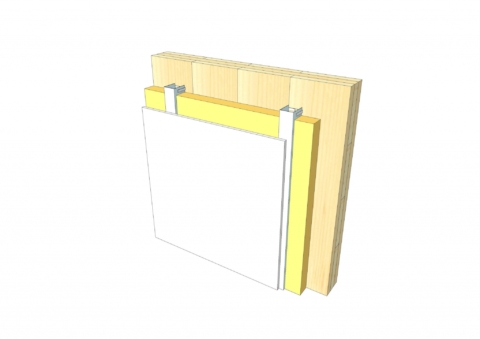

AW_03 | Plaster baseboard

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

48

0.19

30

325

-53

49

0.18

60

338

-51

54

0.17

60

365

-47

55

0.15

90

398

-44

63

0.15

90

410

-43

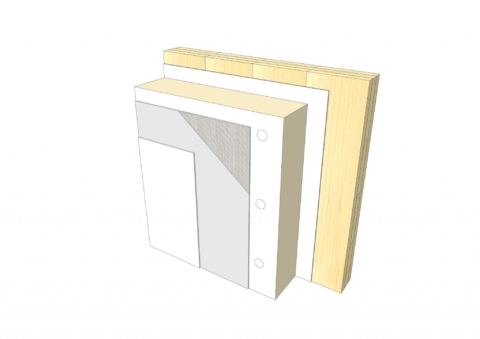

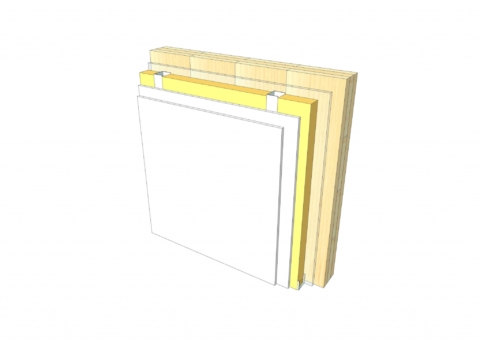

AW_04 | ETICS - EPS

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

36

0.15

30

311

-39

37

0.15

60

324

-36

45

0.14

60

351

-33

47

0.13

90

384

-29

56

0.13

90

396

-29

AW_05 | ETICS - Mineral wool

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

41

0.15

30

311

-37

42

0.15

60

324

-34

46

0.14

60

351

-31

48

0.13

90

384

-28

60

0.13

90

396

-27

AW_06 | ETICS - Wood fiber

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

39

0.17

30

311

-86

40

0.17

60

324

-84

45

0.16

60

351

-81

48

0.14

90

386

-77

59

0.14

90

396

-77

AW_07 | ETICS - Hemp

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

54

0.18

30

311

-51

55

0.18

60

324

-48

57

0.16

60

351

-45

59

0.15

90

386

-41

67

0.14

90

396

-41

IW_01 | KLH® 3s 60

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

29

1.32

-

60

-36

30

1.24

-

73

-34

38

0.76

-

100

-30

40

0.53

-

135

-26

49

0.50

-

145

-26

IW_02 | KLH® 3s 100

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

33

0.91

30

100

-60

34

0.87

30

113

-58

44

0.60

30

140

-54

47

0.45

30

175

-50

59

0.43

30

185

-50

IW_03 | KLH® 5s 160

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

39

0.63

30

160

-96

40

0.61

60

173

-94

48

0.46

60

200

-90

51

0.36

90

235

-86

61

0.35

90

245

-86

IW_04 | Cladded

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

34

0.87

30

113

-58

35

0.84

60

125

-55

45

0.59

60

152

-52

48

0.43

60

188

-48

60

0.42

60

198

-48

IW_05 | Resilient profile

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

44

0.60

30

140

-54

45

0.59

60

152

-52

48

0.45

60

179

-49

50

0.36

60

215

-44

63

0.35

60

225

-44

IW_06 | Facing formwork timber battens

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

41

0.45

30

163

-60

42

0.44

60

175

-57

50

0.36

60

202

-54

51

0.30

60

240

-49

61

0.29

60

250

-49

IW_07 | Facing formwork CW-profiles

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

47

0.45

30

173

-51

48

0.44

60

185

-48

50

0.36

60

215

-44

52

0.30

90

250

-40

62

0.29

90

260

-40

IW_08 | Facing formwork self supporting

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

60

0.43

30

185

-50

61

0.42

60

198

-48

63

0.35

60

225

-43

64

0.29

90

260

-38

70

0.28

90

270

-40

IW_09 | Two layer KLH® 3s 100

Sound Rw [dB]

Thermal U [W/m2K]

Fire R*EI [min]

Thickness [mm]

Ecology [kg CO2 eq./m2]

62

0.26

30

295

-112

64

0.25

60

320

-107

68

0.22

60

347

-104

69

0.20

60

380

-100

73

0.19

60

390

-99