Solid

wood

panels.

KLH® SOLID WOOD PANELS ARE IDEALLY SUITED FOR LOAD-BEARING, BRACING AND NON-LOAD-BEARING WALL, FLOOR AND ROOF ELEMENTS.

Manufacture

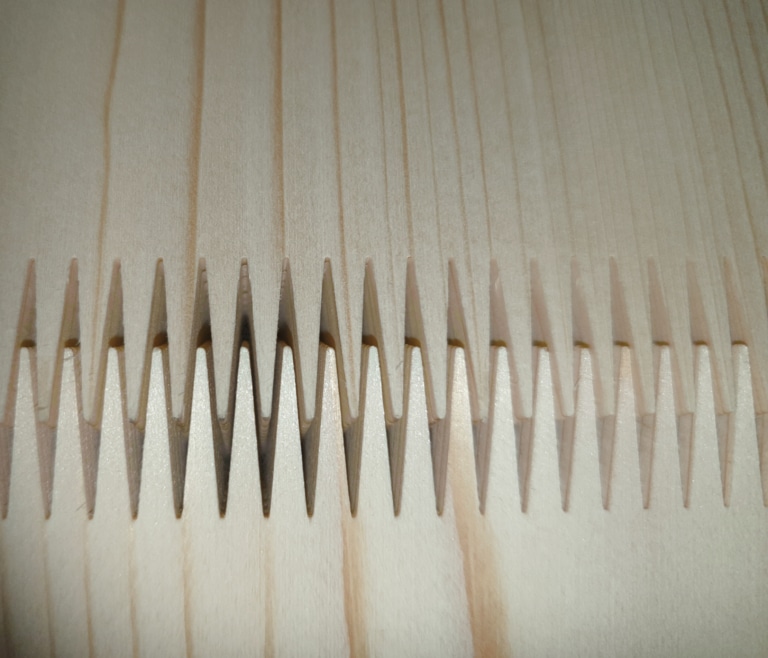

The crossways arrangement of the longitudinal and crosswise laminates reduces the swelling and shrinkage in the board plane to an insignificant minimum and static strength and shape retention increase considerably. According to the European Technical Assessment exclusively technically seasoned timber with a wood moisture content of 12% (+/-2%) is used. Any timber laminates are subjected to quality control before their use.

Adhesives &

lamination process

Only VOC-free and formaldehyde-free PUR adhesives are used in accordance with EN 15425. The adhesives have been tested and classified as TYPE 1 adhesives and have been approved for the production of load-bearing timber components.

The adhesive is applied automatically over the entire surface approx. 0.15 kg/m² per joint. The laminated pressure at 0.6 N/mm² used during the manufacture of KLH® solid timber panels is 6 times higher when compared with vacuum press technology. The quality of the lamination of KLH® CLT is therefore of high quality and the load-bearing capacity comparatively higher.

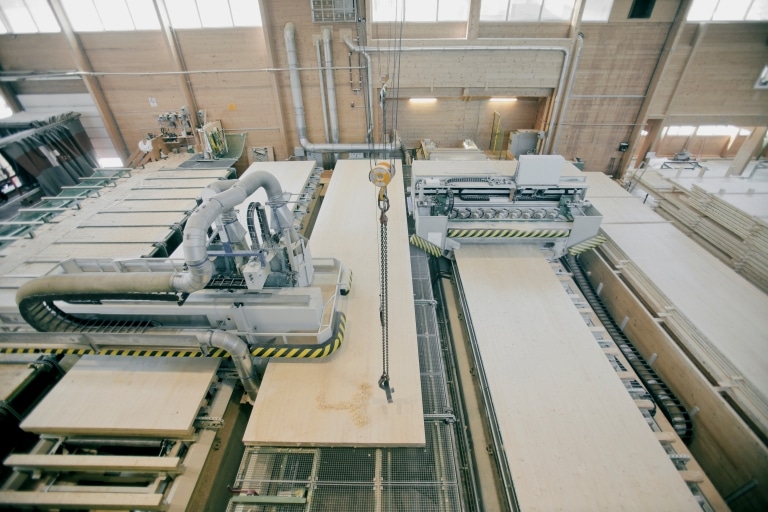

CNC - Cutting

Factory cutting or beaming takes place using state-of-the-art CNC-technology. The basis for that form the production and cutting plans released by the client or the executing company, respectively. For elements of a length and width > 1 m the tolerances are +/-2mm, for standard panel types, standard trimming and a wood moisture content of 12%.

We furthermore produce and deliver unmachined raw panels to supply CNC trimming service factories and processing mills, from where the elements are then transported to the site.

For further information please contact us.

Assembly &

Installation

We are offering various lifting systems, depending on the panel type, panel size and surface quality. All lifting systems installed in our factory are CE-marked.

Technical Approvals, Certificates and Eco-labels

References