cross

laminated

timber.

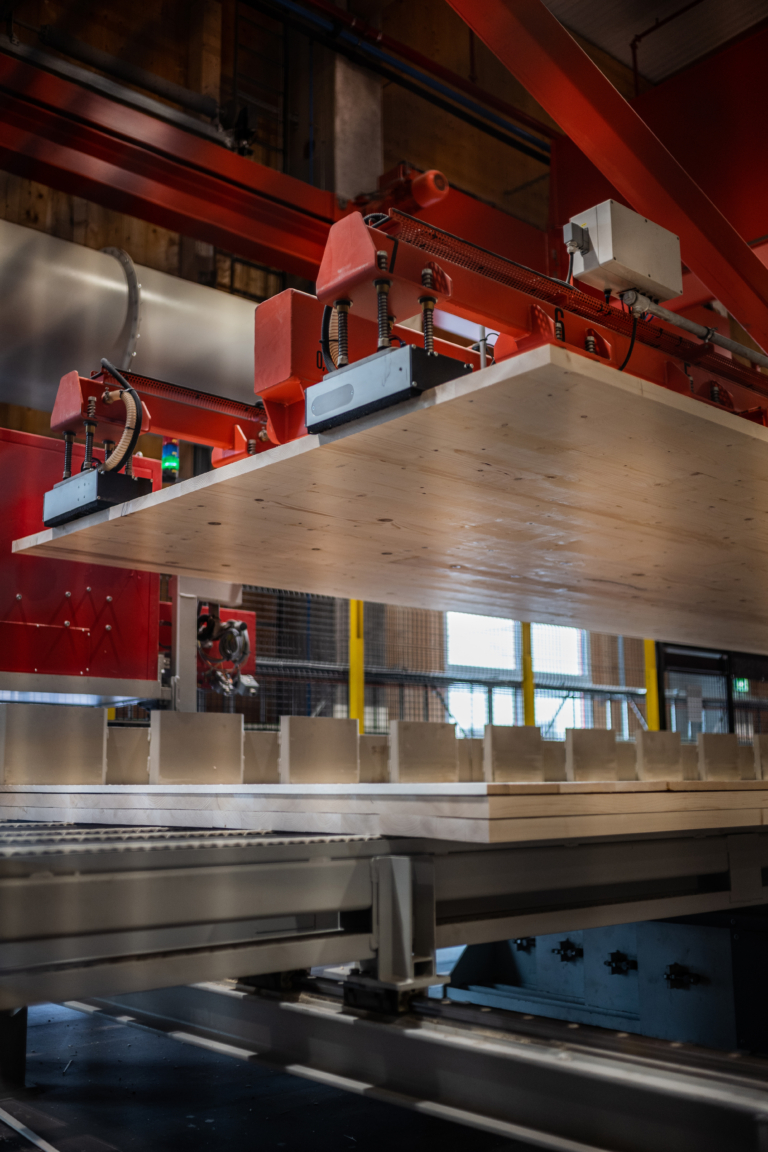

Cross-laminated timber (KLH®, BSP, CLT, X-LAM, Cross-Lam) is made from spruce slats stacked atop of each other which are bonded using high press force and formaldehyde free adhesives to form large-format building elements.

The elements are statically stressed construction elements and are used as wall, floor and roof panels in solid timber construction projects. Thanks to the cross-wise structure of the longitudinal and cross-slats, wood expansion and shrinkage in the panel plane is reduced to an insignificant minimum. At the same time, this raises the structural load capacity and dimensional stability in the panel plane.

In accordance with the European Technical Assessment, technically dried timber with a wood humidity of 12% (+/- 2%) is used for the manufacture of KLH® solid timber boards. Destructive vermin, fungi or insect infestation is thus excluded. KLH® solid timber boards are regarded CE certified building materials. The raw slats used are sourced from sustainably forestry and are either PEFC or FSC® C119602 certified.

Production in

modern facilities.

In our modern production facilities, the elements are exclusively produced in a project-related way. The thickness of the elements and the number of plies used mostly depends on the structural and fire-protection requirements. On the basis of approved production plans, the elements are cut using state-of-the-art CNC systems. The elements are delivered directly to the construction site on a just-in-time basis, either by lorry or in a container. On location, they are mounted by the expert personnel of a timber construction company or that of a construction company using a construction crane.

Technical Approvals, Certificates and Eco-labels

References