Detailed

product

information.

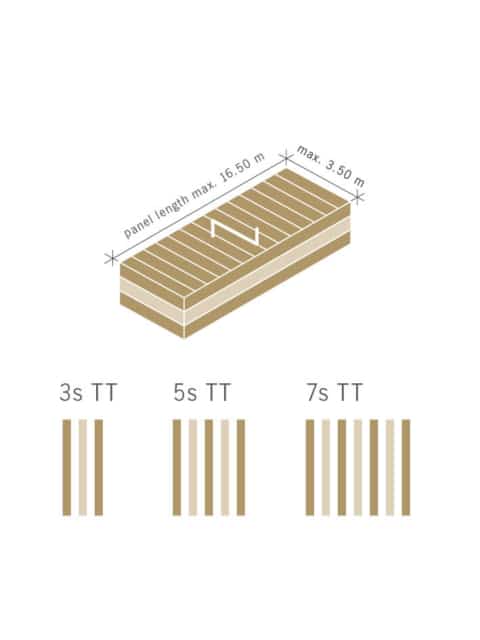

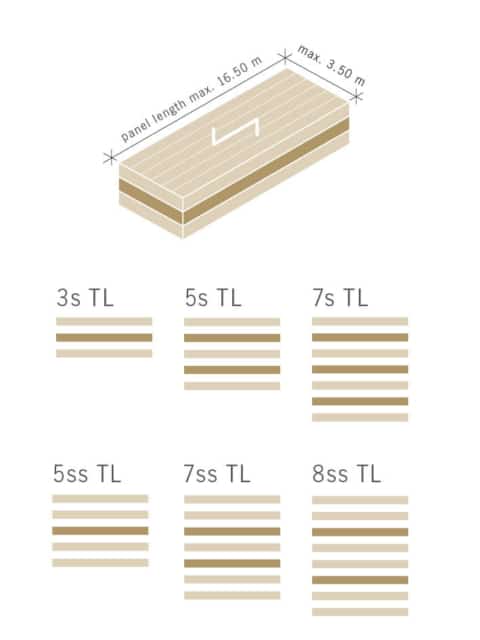

Panel types

KLH® - CLT is offered in 3 standard qualities. Upon request special surfaces and panel built-ups are possible, depending on the availability of the raw lamellas and technical feasibility. Special structures are possible upon request.

By using double layers, the board’s longitudinal and transverse rigidity can be increased in a targeted manner. Changes to the board structure can be used to increase its fire resistance in order to meet special project requirements.

| Nominal thickness in mm | in Layers | Typ | Lamella structure [mm] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | L | C | L | C | L | C | ||||

| KLH® | 60mm | 3s | TT | 20 | 20 | 20 | ||||

| KLH® | 70mm | 3s | TT | 20 | 30 | 20 | ||||

| KLH® | 80mm | 3s | TT | 30 | 20 | 30 | ||||

| KLH® | 90mm | 3s | TT | 30 | 30 | 30 | ||||

| KLH® | 100mm | 3s | TT | 30 | 40 | 30 | ||||

| KLH® | 110mm | 3s | TT | 40 | 30 | 40 | ||||

| KLH® | 120mm | 3s | TT | 40 | 40 | 40 | ||||

| KLH® | 100mm | 5s | TT | 20 | 20 | 20 | 20 | 20 | ||

| KLH® | 110mm | 5s | TT | 20 | 20 | 30 | 20 | 20 | ||

| KLH® | 120mm | 5s | TT | 30 | 20 | 20 | 20 | 30 | ||

| KLH® | 130mm | 5s | TT | 30 | 20 | 30 | 20 | 30 | ||

| KLH® | 140mm | 5s | TT | 30 | 20 | 40 | 20 | 30 | ||

| KLH® | 150mm | 5s | TT | 30 | 30 | 30 | 30 | 30 | ||

| KLH® | 160mm | 5s | TT | 40 | 20 | 40 | 20 | 40 | ||

| Nominal thickness in mm | in Layers | Typ | Lamella structure [mm] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| L | C | L | C | L | C | L | ||||

| KLH® | 60mm | 3s | TL | 20 | 20 | 20 | ||||

| KLH® | 70mm | 3s | TL | 20 | 30 | 20 | ||||

| KLH® | 80mm | 3s | TL | 30 | 20 | 30 | ||||

| KLH® | 90mm | 3s | TL | 30 | 30 | 30 | ||||

| KLH® | 100mm | 3s | TL | 40 | 20 | 40 | ||||

| KLH® | 110mm | 3s | TL | 40 | 30 | 40 | ||||

| KLH® | 120mm | 3s | TL | 40 | 40 | 40 | ||||

| KLH® | 100mm | 5s | TL | 20 | 20 | 20 | 20 | 20 | ||

| KLH® | 110mm | 5s | TL | 20 | 20 | 30 | 20 | 20 | ||

| KLH® | 120mm | 5s | TL | 30 | 20 | 20 | 20 | 30 | ||

| KLH® | 130mm | 5s | TL | 30 | 20 | 30 | 20 | 30 | ||

| KLH® | 140mm | 5s | TL | 40 | 20 | 20 | 20 | 40 | ||

| KLH® | 150mm | 5s | TL | 40 | 20 | 30 | 20 | 40 | ||

| KLH® | 160mm | 5s | TL | 40 | 20 | 40 | 20 | 40 | ||

| KLH® | 170mm | 5s | TL | 40 | 30 | 30 | 30 | 40 | ||

| KLH® | 180mm | 5s | TL | 40 | 30 | 40 | 30 | 40 | ||

| KLH® | 190mm | 5s | TL | 40 | 40 | 30 | 40 | 40 | ||

| KLH® | 200mm | 5s | TL | 40 | 40 | 40 | 40 | 40 | ||

| KLH® | 160mm | 5ss | TL | 30+30 | 40 | 30+30 | ||||

| KLH® | 180mm | 7s | TL | 20 | 40 | 20 | 20 | 20 | 40 | 20 |

| KLH® | 200mm | 7s | TL | 20 | 40 | 20 | 40 | 20 | 40 | 20 |

| KLH® | 220mm | 7s | TL | 30 | 40 | 30 | 20 | 30 | 40 | 30 |

| KLH® | 240mm | 7s | TL | 30 | 40 | 30 | 40 | 30 | 40 | 30 |

| KLH® | 180mm | 7ss | TL | 30+30 | 20 | 20 | 20 | 30+30 | ||

| KLH® | 200mm | 7ss | TL | 30+30 | 20 | 40 | 20 | 30+30 | ||

| KLH® | 220mm | 7ss | TL | 40+40 | 20 | 20 | 20 | 40+40 | ||

| KLH® | 240mm | 7ss | TL | 40+40 | 20 | 40 | 20 | 40+40 | ||

| KLH® | 260mm | 7ss | TL | 40+40 | 30 | 40 | 30 | 40+40 | ||

| KLH® | 280mm | 7ss | TL | 40+40 | 40 | 40 | 40 | 40+40 | ||

| KLH® | 300mm | 8ss | TL | 40+40 | 30 | 40+40 | 30 | 40+40 | ||

| KLH® | 320mm | 8ss | TL | 40+40 | 40 | 40+40 | 40 | 40+40 | ||

Surfaces &

Qualitydefinition

As a standard, we produce KLH® - CLT in spruce and in three different surface qualities, which can be combined as required. This applies without restriction for all the panel types shown previously.

Surfaces treatment and special surfaces

| Domestic Visible (DVQ) | Industrial Visible (IVQ) | Non Visible (NVQ) | |

|---|---|---|---|

| Application Area | Visible components in residential, school or office constructions, especially suitable for residential areas and surfaces with glazes. | Visible components in industrial and office buildings, not recommended for residential constructions. | Pure structural components with subsequent panelling. |

| Demand towards Surface | high demand | medium demand | no demand |

| Production-Related References | chamfer on TL panels (in the panel width joint) | chamfer on TL panels (in the panel width joint) | no chamfer |

| Surface Finishing In-Plant | fully sanded (one- or double sided) | fully sanded (one- or double sided, individual small rough areas permitted) | equalised (planed or sanded) |

| Surface Treatment In-Plant | Protective coatings & surface refinement on request | Protective coatings on request, not recommended for surface refinement | protective coatings on request, surface refinement not available |

The minimum requirements for each surface described refer to the time of delivery. For narrow sides and CNC-treated surfaces, the criteria for non-visible surfaces apply.

| Criteria | Domestic visible (DVQ) | Industrial visible (IVQ) | Non visible (NVQ) | |

|---|---|---|---|---|

| Surface treatment | sanded | sanded, individual small rough areas permitted | equalised (planed or sanded) | |

| Type of wood | one type of wood | one type of wood; spruce / fir (≤ 10 %) are regarded as one type of wood | addition of other types of wood possible | |

| Colour and texture | mostly balanced | generally balanced | no requirements | |

| Blue and brown stains, red tinge | slight discolouration permissible (≤ 3 %) | slight discolouration permissible (≤ 5 %) | no restrictions | |

| Branches, tightly intergrown | permissible | permissible | no restrictions | |

| Branches, black | permissible ≤ 25 mm Ø | permissible ≤ 35 mm Ø | no restrictions | |

| Loose knots, knot holes | permissible ≤ 12 mm Ø | permissible ≤ 15 mm Ø | no restrictions | |

| Resin pockets | sporadically permissible ≤ 3 x 50 mm | sporadically permissible ≤ 5 x 70 mm | no restrictions | |

| Piths | sporadically permissible length ≤ 800 mm | sporadically permissible length ≤ 1000 mm | no restrictions | |

| Bark ingrowth | impermissible | impermissible | no restrictions | |

| Wane | impermissible | impermissible | permissible | |

| Compression wood | sporadically permissible | sporadically permissible | no restrictions | |

| Cut burrows from inactive insect infestation | impermissible | impermissible | sporadically permissible | |

| Wood moisture during production | ≤ 12 % | ≤ 13 % | ≤ 14 % | |

| Cracks and joints (at a reference moisture measurement of 12 %) | sporadically permissible ≤ 1,5 mm | sporadically permissible ≤ 2 mm | sporadically permissible ≤ 6 mm | |

| Surface defects | sporadically permissible ≤ 12 mm Ø | sporadically permissible ≤ 15 mm Ø | no restrictions | |

| Surface re-treatment (Filling and plugging of branch holes, strips, etc.) | permissible | permissible | no restrictions | |

| Defects on cutting edges | sporadic small defects permissible | sporadic defects permissible | no restrictions | |

| Cutting edge re-treatment manually, using sand paper | yes | yes | no | |

| Chamfer on TL panels (in the panel width joint) | yes | yes | no | |

| Range of validity | The given surface qualities valid: - at the time of delivery - only for the covering layer, not for the narrow sides - for one-sided visible surfaces - for narrow sides and CNC-treated surfaces, the criteria for NVQ surface quality apply - for double-sided visible surfaces, a small amount of on-site reworking is to be expected |

|||

| Crack formation | Like all solid wood products, the above stated qualities are subject to crack and joint formation as a result of drying to their future compensation moisture balance when installed due to the product characteristics. This cannot be prevented. Especially in the first few years, cracking noises can also occur alongside the formation of cracks, which can be classified as harmless. Particularly in the case of surfaces in visible quality, make sure to avoid strong fluctuations in the room climate both during the construction phase (for example, when the screed is drying) and during the use phase. The ideal air humidity is between 40 - 60%. Particularly with white glazed surfaces, there may be an undesired and irreversible contrast due to crack/gap formation. Please advise building owners and instruct all subsequent trades during the construction phase accordingly. |

|||

| Note | Wood is a natural product. Minor deviations from the table values are natural and are no reason for complaint. | |||

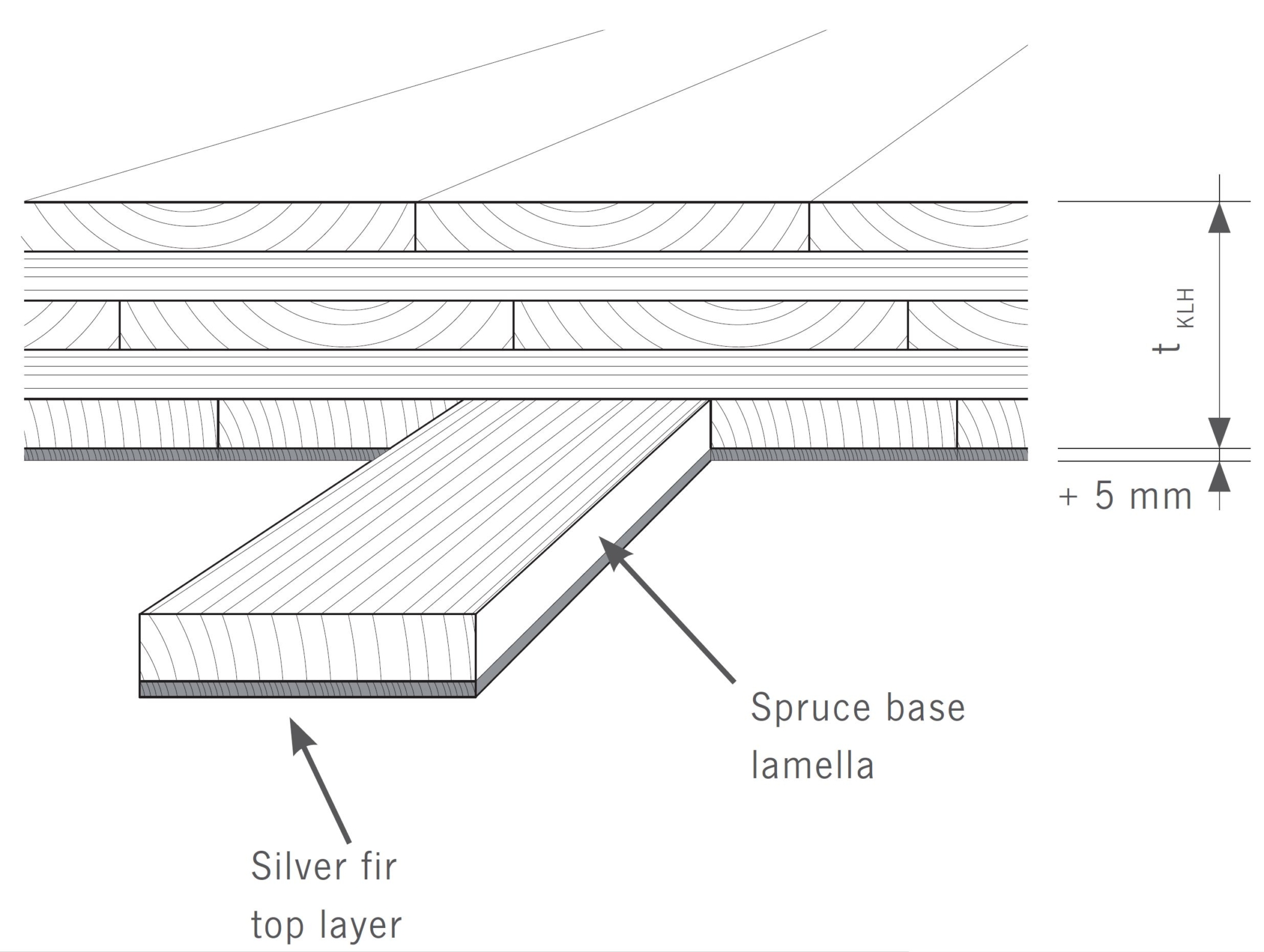

| KLH® Select Silver Fir (DVQTA) | |

|---|---|

| Application area | Precious wood surface for visible components in residential buildings, especially suitable for sophisticated architecture and largely knotless appearance |

| Demands on the surface | Highest demands, ideally flawless and free of knots, balanced wood texture, very balanced, homogeneous appearance with colour tolerances that are typical of fir wood |

| Productionrelated references | Panel thickness +5 mm (for one-sided, non-load-bearing top layer of silver fir), single board width approx. 100 mm, single board length approx. 1 – 2 m, finger-jointed |

| Surface finishing | Finely sanded over the entire surface (one side), surface re-treatment (knothole filling, strips, etc.) permitted |

| Surface treatment in-plant | Finishing possible on request |

Technical

characteristics

| Product name / Brand | KLH® - CLT |

| OTHER PRODUCT NAMES | Cross-laminated timber (CLT) | X-Lam |

| APPLICATION | Structural elements for walls, floors and roofs |

| DURABILITY | Service classes 1 and 2 according to EN 1995-1-1 |

| WOOD SPECIES | Spruce (pine, fir, stone pine and other wood types on request) |

| PANEL BUILD UP | 3, 5, 7 or more layers depending on static requirements |

| LAMELLAE | Thickness 20 to 45 mm, technically dried, quality-sorted and finger-jointed |

| STRENGTH CLASS | C 24 according to EN 338, maximum 10% C 16 permitted (compare ETA-06/0138) |

| ADHESIVE | Formaldehyde-free PUR adhesive, approved for load-bearing and non-load-bearing components indoors and outdoors according to EN 15425 |

| LAMINATING PRESSURE | At least 0.6 N/mm² |

| WOOD MOISTURE CONTENT | 12% (+/- 2%) on delivery |

| MAXIMUM ELEMENT DIMENSIONS | Length 16.50 m / width 3.50 m / thickness 0.50 m |

| INVOICING WIDTHS | 2.45 | 2.50 | 2.73 | 2.95 | 3.10 | 3.20 | 3.30 | 3.40 | 3.50 m |

| CUTTING TOLERANCES | For elements of a length and width > 1 m the tolerances are +/-2 mm, for standard panel types, standard trimming and a wood moisture content of 12% |

| SURFACE QUALITY | Non-visible quality (NVQ) | Industrial visible quality (IVQ) | Domestic visible quality (DVQ) Special surfaces on request |

| WEIGHT | 5.5 kN/m³ according to ÖNORM B 1991-1-1:2011 for structural analysis 500 kg/m³ for determination of transport weight |

| MOISTURE MOVEMENT | In panel plane 0.02% per % change in wood moisture content, perpendicular to panel plane (panel thickness direction) 0.24% per % change in wood moisture content |

| THERMAL CONDUCTIVITY | λ = 0.12 W/(m*K) according to EN ISO 10456 |

| HEAT STORAGE CAPACITY | cp = 1600 J/(kg*K) according to EN ISO 10456 |

| VAPOUR RESISTANCE | µ = 300 (dry) to 46 (wet) according to EN ISO 12572 |

| AIR TIGHTNESS | KLH® - CLT can generally be used as airtight layers (Class 4 acc. to EN 12207). Connections to other components, butt joints, penetrations, etc. must be sealed appropriately. |

| REACTION TO FIRE | Euro class D-s2, d0 |

| RESISTANCE TO FIRE | Fire analysis parameters acc. to ETA - 06/0138 |

Protective coatings &

Surface refinement

With the increasing use of wood as a building material, increases also the demand for coated and surface-finished cross-laminated timber elements. As of now, we offer KLH® elements treated with protective coatings or with a surface finish mechanically applied in our factory.

| ORDERING CODE | PRODUCT | EXECUTION OF THE COATING | SURFACE APPEARANCE | APPLICATION AREA | HSB CODE |

| REMMERS 910 | Induline SW-910 | One layer | Colourless | Water-based end grain sealer for protection of edges and cut edges against moisture | 03-02 |

| REMMERS 732 WF | Induline LW-732 WF | One layer full-surface on one or both sides, with or without edges and cut edges | Colourless, slightly shiny | Water-emulsified middle layer glaze for temporary protection against moisture and dirt on visible and non-visible surfaces (glulam protective layer) | 04-02 |

| REMMERS 900 IT | Induline SW-900 IT | One layer full-surface on one or both sides, with or without edges and cut edges | Colourless | Water-based impregnation for protection against soft rot, blue stain, insects and termites (class 2 treatment), not suitable for indoor application service class 1 | 02-02 |

| REMMERS 900 IT | Induline SW-900 IT | One layer with intermediate sanding | Colourless | Wood protection for factory combination with surface refinement, not suitable for indoor application service class 1 | 02-06 |

| ORDERING CODE | PRODUCT | EXECUTION OF THE COATING | SURFACE APPEARANCE | APPLICATION AREA | HSB CODE |

| REMMERS 810 | Induline OW- 810 | Two-layer with intermediate sanding, on one visible side | Colourless oil, slightly shiny | Intermediate and final coating for refinement with water-based UV protection | 06-03 |

| REMMERS 716 WF | Induline LW-716 WF | Two-layer with intermediate sanding, on one visible side | Colourless, matt glaze | Refinement of visible surfaces with water-based UV protection | 05-03 |

| REMMERS AL RC 990 (50%) | All-purpose stain RC-990 (50%) | Two-layer with intermediate sanding, on one visible side | White-glazing 50% | Decorative water-based middle layer glaze with UV protection | 09-03 |

| REMMERS AL RC 990 (100%) | All-purpose stain RC-990 (100%) | Two-layer with intermediate sanding, on one visible side | White-glazing 100% | Decorative water-based middle layer glaze with UV protection | 07-03 |

| ORDERING CODE | APPLICATION AREA | HSB CODE |

| KLH PROTECT | The diffusion-capable, sturdy, full-surface self-adhesive membrane serves to protect KLH® elements against moisture during storage, transport, assembly and the building phase. | 31-00 |

Technical Approvals, Certificates and Eco-labels

Mi